Prelude Overview

Prelude is an operational floating liquefied natural gas (FLNG) facility, located offshore, north-north east of Broome in Western Australia.

Find out more about Prelude by watching the video, or scroll down to learn more.

Read the transcript

Read the transcript

Title: Proud to be Prelude.

Duration: 5’05” minutes

Description:

Meet the team behind Shell’s first floating LNG facility.

___________________________________________________

[Background music plays]

Orchestral music featuring synthesized musical effects.

[Video footage]

Aerial shot of a worker standing on a helideck of Prelude FLNG facility. Shot of dawn rising over facility. Camera pulls in to Prelude OIM Mark Greene on the bow of the facility, Mark talks to camera.

[Title: Mark Greene Prelude OIM] [Dialogue, Mark]

G’day and welcome to Prelude, Shell’s first floating LNG facility right here off the coast of North Western Australia. We’re mighty proud of what we’ve achieved out here, in fact, we’re the largest floating facility ever built. So let me take you on a journey to find out what makes Prelude so special.

[Background music swells] [Video footage] [Title: Broome]

Images of camels walking on beach. We see sign of Broome helicopter terminal. Gimbal shot tracking a helicopter being wheeled into the hangar. Camera follows CHC helicopter pilot Martin Rock as he walks through the hangar.

[Dialogue] [Title: Martin Rock, Pilot]

And Here is where your trip begins right here in Broome. The Prelude is 550 km’s away or two and half-hours with helicopter. And I’m one of the pilots that will make your flight as smooth as possible.

[Video footage]

Helicopter is wheeled onto runway, passengers board and helicopter takes off into the sky.

[Background music swells] [Video footage] [Title: Djarindjin Airport]

Aerial shots of Djarindjin airport runway. Helicopters arriving, touching down in remote location, people get off helicopters, workers refueling helicopters. Kim Baird walks towards the camera.

[Title: Kim Baird, Djarindjin Airport Manager] [Dialogue]

Welcome to Djarindjin Airport in Bardi Jawi country. This is where we refuel all the Helicopters before they go offshore. That means plenty of jobs for my kids and my community.

[Video footage]

Kim turns to two helicopter refuellers on runway.

[Dialogue, Kim]

“How you doing boys?”

[Video footage]

Images of refuellers, fishing and hunting in the waterways of One Arm Point, Cape Levique, before helicopter flies out of camera.

[Dialogue, Kim]

So we can work and live on our country.

[Video footage]

Camera pans down to reveal image of Prelude FLNG on location.

[Background music swells] [Video footage] [Title: Prelude FLNG]

Sam Palmer, standing on Prelude’s green mile.

[Title: Samantha Palmer, Production Technician] [Dialogue, Sam]

We call this the green mile. It’s where we process and liquefy the natural gas.

[Video footage] [Title: Priya Khanna, Production Technician]

Priya Khanna, on Prelude’s living quarters.

[Dialogue, Priya]

We chill the gas to -162 degrees, which liquefies it, so we can send it anywhere in the world.

[Video footage]

Josh Butler, on Prelude’s topside module. Images of people working on Prelude FLNG, time-lapse shot of Hong Kong.

[Title: Josh Butler, Production Technician] [Dialogue, Josh]

These modules are designed to produce over 3 and a half million tonnes of LNG each year. Enough for a city as big as Hong Kong.

[Dialogue, Sam]

And with half the emissions of coal, natural gas is also better for the environment.

[Video footage] [Title: Andrew Court, Master]

Image of Andrew Court walking down the deck of the Roebuck Bay.

[Dialogue, Andrew]

But all that LNG can’t go anywhere without us. Welcome to the Roebuck bay.

[Background music swells] [Video footage] [Title: Roebuck Bay]

Image of Roebuck Bay intercut with crew working on the ISV.

[Dialogue, Andrew]

We have 3 ISV’s, just like this one, to support the facility and to berth the offtake tankers. In fact, we’ve got one coming in right now.

[Video footage]

ISV’s berthing LNG tanker at Prelude FLNG.

[Radio dialogue pilot]

Roebuck quarter power.

[Radio dialogue ISV master]

Roebuck Bay quarter power.

[Video footage]

Prelude Head Chef Abeeza Bhamgara, talking to camera.

[Title: Abeeza Bhamgara, Head Chef] [Dialogue, Abeeza]

And I have got the most important job on Prelude.

[Background music swells] [Video footage] [Title: The Prelude Kitchen]

Chefs in morning meetings, intercut with shots of people eating and the Prelude kitchen cooking meals.

[Dialogue, Abeeza]

Specials today, we’ll have pancakes, whipped cream on side and berry compote.

[Dialogue, Abeeza]

They’re hungry boys and girls out here and our food here on Prelude, is best food you’ll see anywhere offshore. Prelude is just not a gas plant. It’s a floating hotel.

[Video footage]

Man strikes golf ball in simulator, shots of people working out at gym and sunrise as people do a yoga class on the Prelude helideck.

[Title: Paul Stoke, Wellness Coach] [Dialogue, Paul]

And this may be the most remote yoga class in the world.

[Video footage]

Aerial shots of Prelude yoga class as sun breaks over horizon.

[Video Footage] [Title: Scott Rains, Supply Base Manager]

Scott Rains walks down store room aisle, turns and talks to camera.

[Dialogue, Scott]

Now Prelude is the biggest offshore facility in the world. But it also takes a huge onshore team to make it possible.

[Video footage]

Wide shot of supply base in Darwin.

[Dialogue, Scott]

And this is our supply base in Darwin.

[Background music swells] [Video footage] [Title: Darwin]

Activity Darwin supply base, trucks arriving, people moving about, packing boxes, driving forklift trucks. Crates being loaded onto vessel at Port of Darwin.

[Dialogue, Scott]

From safety equipment to electrical gear, anything that goes to Prelude comes through this supply base.

[Video footage]

Scott talking into radio, as truck loads.

[Dialogue, Scott]

Yeh mate, you can start lowering.

[Dialogue, Scott to camera]

In fact, we’re getting ready for a load out right now.

[Video footage]

Andrew Farrell talking to camera walking through industrial setting

[Title: Andrew Farrell, Rusca Environmental Solutions]

And everything that comes off the facility goes through us.

[Video footage]

Shots of workers sorting tin cans, plastic bottles, ready for processing.

[Dialogue, Andrew]

All of Prelude’s waste is transferred to us here in Darwin, where we recycle up to 70% of everything. Our job is to look after the environment for generations to come. And we’re a 100% owned indigenous company.

[Video footage]

Andrew with his colleagues at Rusca Environmental Solutions.

[Background music swells] [Video footage] [Title: Perth]

Image of Shell House in Perth.

[Video footage] [Title: Joanne Mitchell, Senior Process Engineer]

Jo Mitchell walking to camera, in Prelude CWE. Workers in office, at computers, having meetings, and two-way conferences with Prelude offshore.

[Dialogue, Jo]

We call this the CWE. Some people call it the Starship Enterprise. 24 hours a day, 7 days a week, we support Prelude with the best technology in the world. You probably get better internet speeds out there, than you do back at home.

[Video footage]

Meeting between Perth and offshore team.

[Dialogue, worker 1]

I actually managed to get the ops guys to do a pump test yesterday.

[Dialogue, worker 2]

That action is now closed.

[Video footage] [Title: Stacey Dowling, Process Engineer]

Stacey returning home from work.

[Dialogue, Stacey]

There’s a big team working on Prelude, but these are the people that support us the most.

[Title: Family] [Video footage] [Background music swells]

Stacey’s baby daughter sees her and runs to give her a big hug and kiss.

[Dialogue, Stacey]

And that’s why getting home safely to our families, should always be our number one priority.

[Video footage]

Various, aerial shots of Prelude FLNG, we see Prelude OIM Mark Greene standing on helideck.

[Dialogue, Mark]

So, this is Prelude, Shell’s first floating LNG facility. What makes it so special, isn’t the technology or the size of the facility. It’s the people we’ve got working right across Australia.

[Background music swells] [Video footage]

Fast cut montage of Prelude workers smiling to camera. Followed by Mark Greene back on camera.

[Dialogue Mark]

And that’s why I’m proud to be part of Prelude. Thanks for stopping over. Maybe we’ll see you out here one day.

[Video footage]

Mark turns and walks away. We cut to a wide shot showing full scale of Prelude FLNG as Mark walks out of shot. Fade to black.

[Music ends]

[Graphic]

Shell Pecten, with text #MakeTheFuture.

What is Prelude?

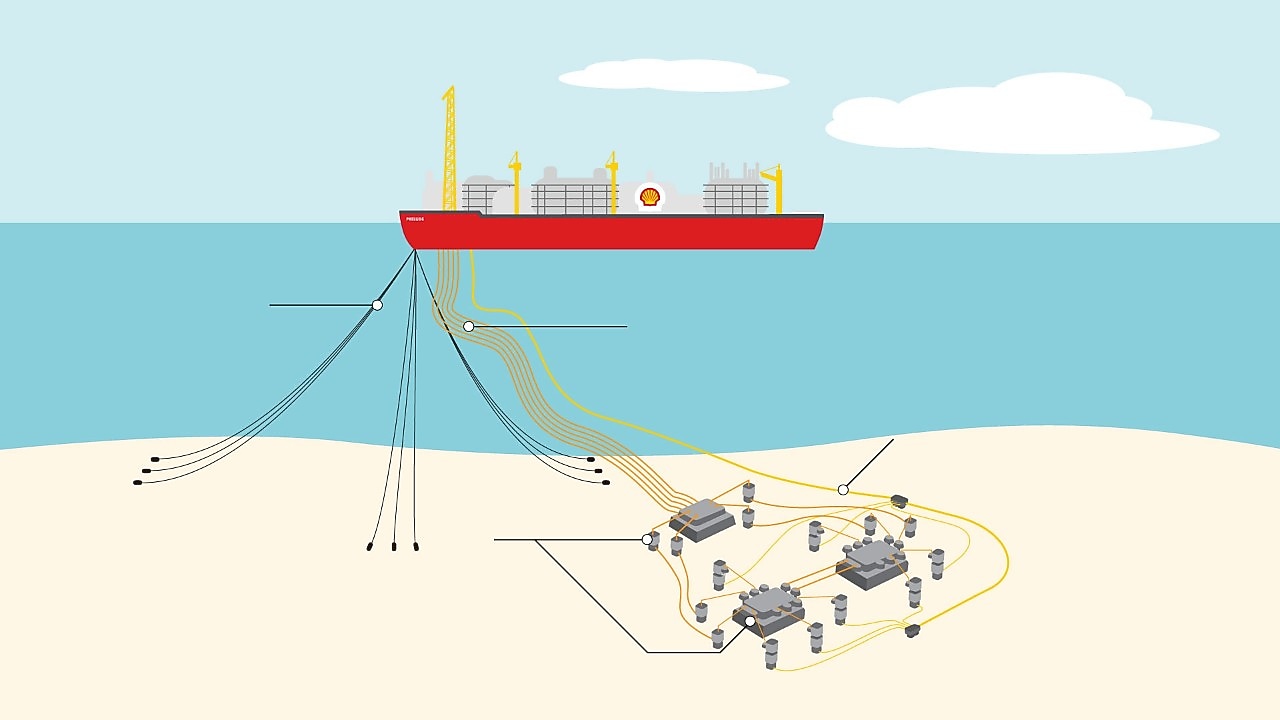

The Prelude FLNG facility is 488m long and 74m wide. It has been designed to remain moored in the field for at least 25 years. Prelude FLNG is designed to extract, liquefy and store natural gas at sea, before it is transferred and shipped to customers.

The technical components of Prelude’s subsea infrastructure

Anchor chains

The Prelude FLNG facility is connected to a series of anchor chains which secure the facility to the seafloor.

Flexible risers and flowlines

There are four, 12-inch flexible risers below the Prelude facility. LNG Products are transferred to Prelude by four 12-inch flowlines.

Subsea system hardware

The subsea system is made up of hardware that includes wellheads, subsea Christmas trees, production manifolds and a riser-based manifold.

Umbilical

The steel tube umbilical provides power and hydraulics to control the subsea system hardware.

What happens at Prelude?

LNG is made by taking water and other impurities out of the gas and cooling it to minus 165 Celsius. Condensate is also produced during the process, which is a light hydrocarbon, somewhat like diesel.

After processing, the gas is transferred onto carrier vessels and transported to customers throughout the world.

Prelude is supported by three infield support vessels, which provide security surveillance, emergency standby and product transfer support. Other multi-purpose supply vessels provide additional transport and logistical support, out of Darwin.

The offshore infrastructure is supported by onshore servicing. The helicopters which transfer personnel to and from Prelude are refuelled at the Djarindjin Airport, which is Aboriginal owned and employs local people.

Prelude has an onshore supply base located in Darwin, Northern Territory, which houses equipment and spare parts.

Shutdowns for maintenance are expected to be needed every four years. Underwater equipment is designed to require minimal maintenance and is inspected regularly.

Where is Prelude?

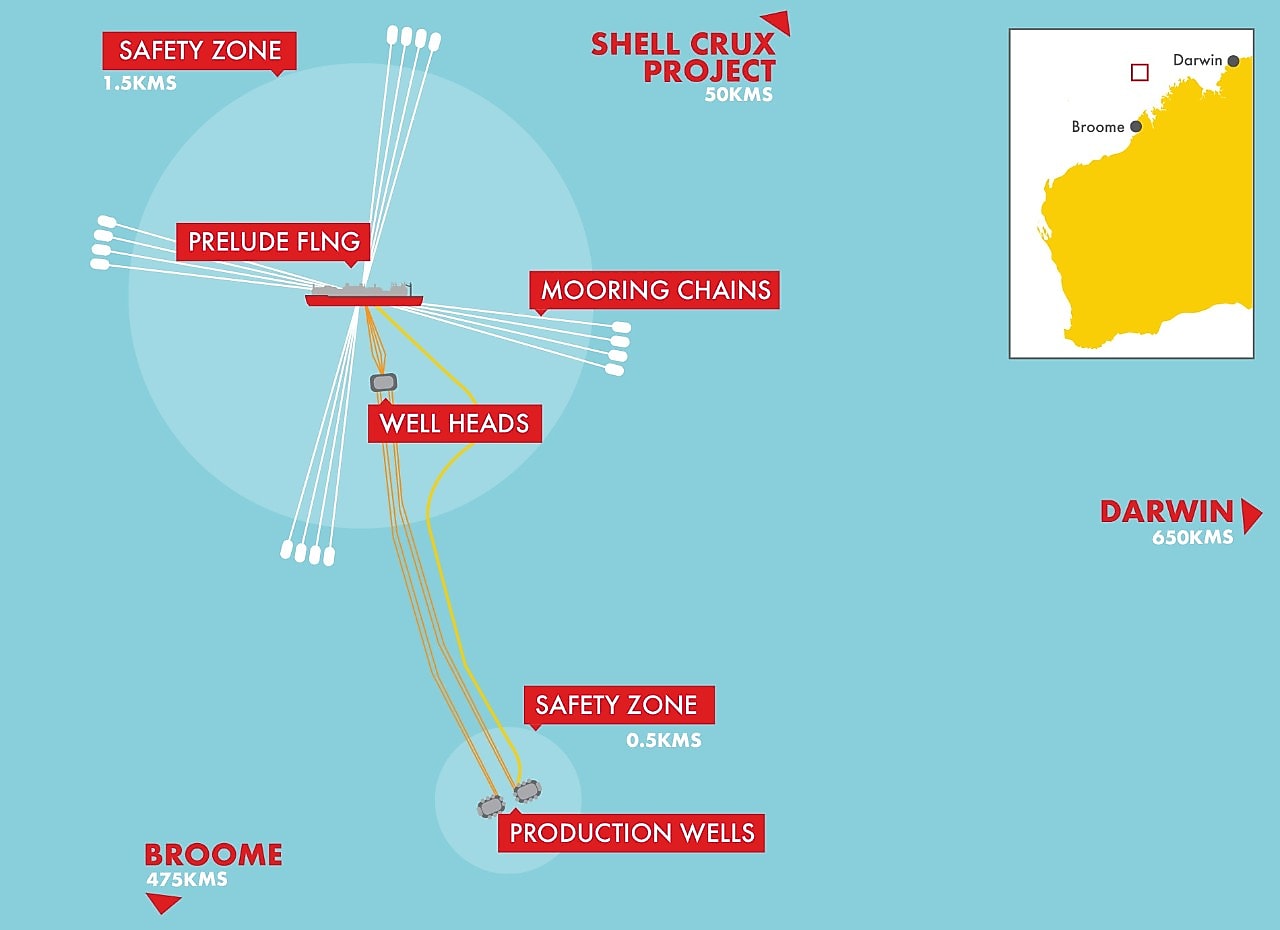

Prelude is located approximately 475km north-east of Broome, Western Australia, in the Browse Basin.

Prelude’s safety zone extends in a 1.5km radius around the facility.

What is an Environment Plan?

An Environment Plan, or EP, outlines all the environmental impacts and risks of an activity and how these are managed to minimise risks to the environment. It is required by the National Offshore Petroleum Safety and Environmental Management Authority (NOPSEMA) for approval (acceptance), prior to starting an offshore oil and gas activity. NOPSEMA requires all EPs extending longer than five years to be revised.

Shell plans to submit a five-yearly revision of the Prelude EP to NOPSEMA in 2025.